A potential risk for patients and/or test subjects on a motorized treadmill can arise if the running belt stops unexpectedly and quickly.

Such an unexpected stop can occur at any time due to a power failure in the building, an overload, incorrect operation of the device, a lightning strike in the power grid, an unexpected end to an automatic program profile, a perturbation program, an unintentional activation of an emergency stop device, e.g., a magnetic ripcord, a light barrier, or a fall stop device via a safety bar and chest harness, or even an object (e.g., a towel, etc.) that accidentally falls onto the running surface and is pulled into te running belt. But a defect in a treadmill or the integrated technology can also lead to an unexpected braking or rapid stop of the running belt.

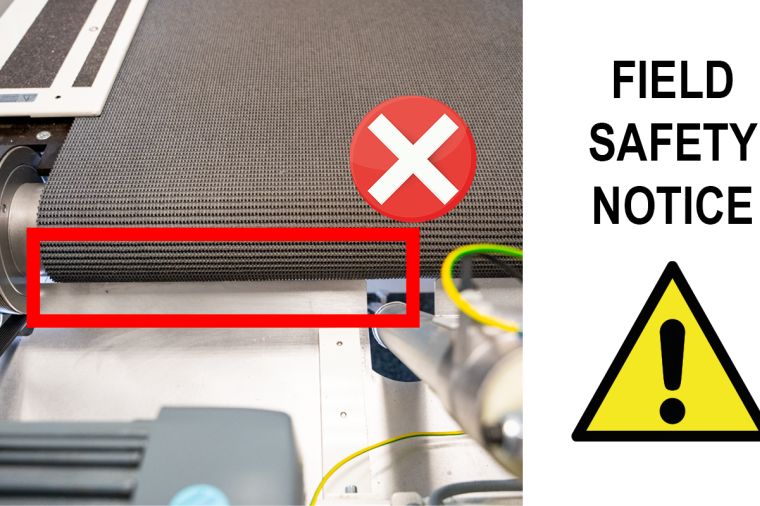

During an internal performance test in a controlled and safe environment, an incident occurred that can be attributed to a specific design feature. The cause was an insufficient gap between the grip protection plate in the motor compartment area and the front drive shaft or running belt. This incident was immediately analysed and appropriate steps were taken to optimise the technology in order to prevent similar situations in future applications.

At a speed of approximately 9 km/h, loud grinding noises were initially heard, followed by an unintentional deceleration of the treadmill drive at approximately 12 km/h, which led to a rapid stop of the running belt. Neither a fall nor an injury to the test person on the treadmill occurred. During this stress test, the runner was secured by the safety arch with fall protection/fall stop [cos10170xx] and a chest harness.

A closer analysis revealed that, theoretically, up to 63 h/p/cosmos treadmills of the above-mentioned models and serial numbers manufactured in 2025 could experience such an unexpected deceleration due to overload.

In isolated cases, the grip protection plate may be set too close to the front drive shaft due to the installation using slotted holes, which may result in the belt coming into contact with the shaft under high loads. This is noticeable in a grinding noise, which can lead to the running belt slowing down and stopping. The motor drive itself is overload-proof, so that an overload or shutdown cannot result in a defect in the motor or drive.

Customer safety and satisfaction, as well as compliance with all normative and regulatory requirements, are top priorities at h/p/cosmos. We would therefore like to inform all customers and users of these theoretically affected treadmills as a preventive measure to ask them to check the devices and, where necessary, make improvements, e.g. by adjusting the gap or replacing the grip protection plate with a modified version [cos12529-07].

The inspection and optimisation can be carried out by certified technicians and/or authorised dealers.

To do this, the gap between the handle guard in the motor compartment and the running belt on the front drive shaft is measured. According to the applicable protection class IP20, the gap may be up to 12.5 mm.

A new standard gap dimension of 10 ± 2 mm is specified for the newly designed handle guard plates [cos12529-07].

However, in almost all cases, it is also possible to adjust the grip protection plates in the field using the elongated holes to ensure sufficient clearance from the running belt/shaft, and a gap of 5 mm to 7 mm can be sufficient.

Due to manufacturing tolerances, however, it may happen that the adjustment range of the grip protection plate is insufficient, and in this case, the grip protection plate on one of the affected devices must be replaced with a new type. This gap must also be maintained during subsequent repair work if the grip guard plate was removed on-site.

DOWNLOAD the full PDF

Please allow us to take this opportunity to reiterate the mandatory steps for minimising potential risk:

- Provide adequate training to users and operators on how to operate the treadmill, point out all warnings, and follow them. Use the Installation, Commissioning, and Training Report form for this purpose. cos15228-05_en_de

- Explain and practice the emergency descent from treadmills as described in the operating instructions

- Supervise the operation of the treadmill as described in the instruction manual IFU and never leave children or patients alone on the treadmill.

- Temporarily lock the treadmill if you suspect a defect and inform service@hpcosmos.com

- Lock the treadmill against unauthorized use.

MCU6 TouchScreen: “Option OP 200” Access code required for operation. operation manual IFU “Options > User Options”

MCU5: “Option OP 40“ in chapter 5.11 “Optional settings User Options”

- Use the safety arch with fall protection / fall stop [cos10170xx] with chest harness or a weight relief system (e.g. airwalk ap) as fall protection for any application where a fall represents an unacceptable risk, e.g. during stress tests and/or high speeds, for recently operated hip joint patients, for osteoporosis, for probes in the body, etc.

For questions and/or support and/or PMS observations, please send an email to service@hpcosmos.com

See also the official h/p/cosmos website:

https://www.hpcosmos.com/en/safety

https://www.hpcosmos.com/en/manuals

Please forward this FSN Field Safety Notice to all treadmill users in your facility.

We apologize for any inconvenience this may cause and thank you very much for your co-operation.

h/p/cosmos sports & medical gmbh

Service and Quality Management

phone +49866986420 fax +498669864249